Building the Basics

Now that the aluminium frame was completed, you'd think that all one had to do is tack the fascia pieces on and move forward, right? Well, sure! Only... oh, not.No matter how easy something is, there's always that slight chance for you to do something... well, utterly stupid. Chris forgot that age-old adage of "Measure twice, cut once..." and ended up enjoying a nice little break while waiting for some of his panels to get cut all over again. Oopsie!

To quote him directly:

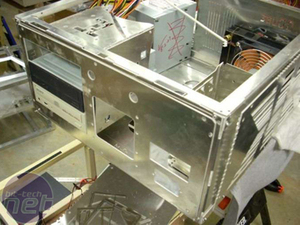

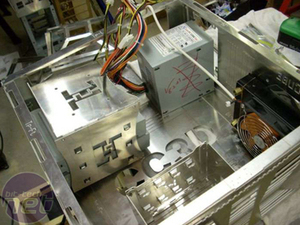

"Anyway, it was time to start putting things together. I pieced the whole thing together to see where I screwed up. This is the point that I discover all my design mistakes. Thanks to the machine-ability of aluminium, my mistakes are usually corrected easily."

But, while corrections were on their way, he stayed a busy boy - not only playing with the radiator design, but also piecing together the bits that didn't get mis-cut.

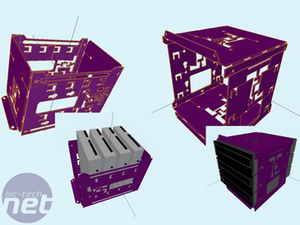

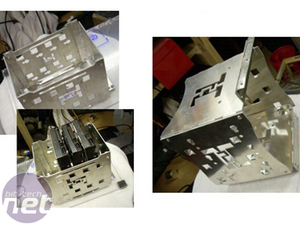

The 3.5- and 5.25-inch bays weren't affected with the measuring mistakes, so Chris decided to get them tacked together. After a test fit to make sure that he indeed did get them cut to size, it was time to rivet them together and move on.

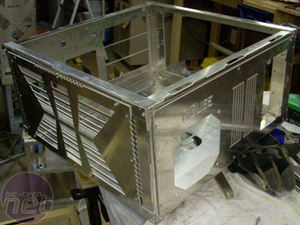

Once the new versions of the side panels came back, the next part of the basic assembly could begin. However, at this time it was more of a test fit - after all, he'd already been burned once on measurement error!

Outside dimensions are far from the only thing that needed to be checked on. Many of the panels had cuts which were designed for certain pieces of hardware - fans, radiators, disk drives - and the fit would be crucial to the final project. Because of that, Chris decided to do a complete test-fit of the lower half of Phase III before moving on.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.